Three Steps to Sizing Plumbing Piping Systems

Sizing plumbing piping systems is not a difficult task when you have the resources to calculate the correct size pipe. The International Plumbing Code (IPC) includes a variety of charts to assist you to properly size plumbing piping systems. Once you understand how to use these charts, you can quickly complete uniform and easily built plumbing systems in buildings. There are three steps to calculating the proper size for a plumbing piping system:

Add up the total number of water supply fixture units (wsfu) required in the facility

Estimate demand using the table from the IPC that correlates wsfu to expected demand

Size the pipe using demand vs. friction loss curves found in the IPC charts

Following is an explanation of each of these steps and instructions on using the related IPC charts.

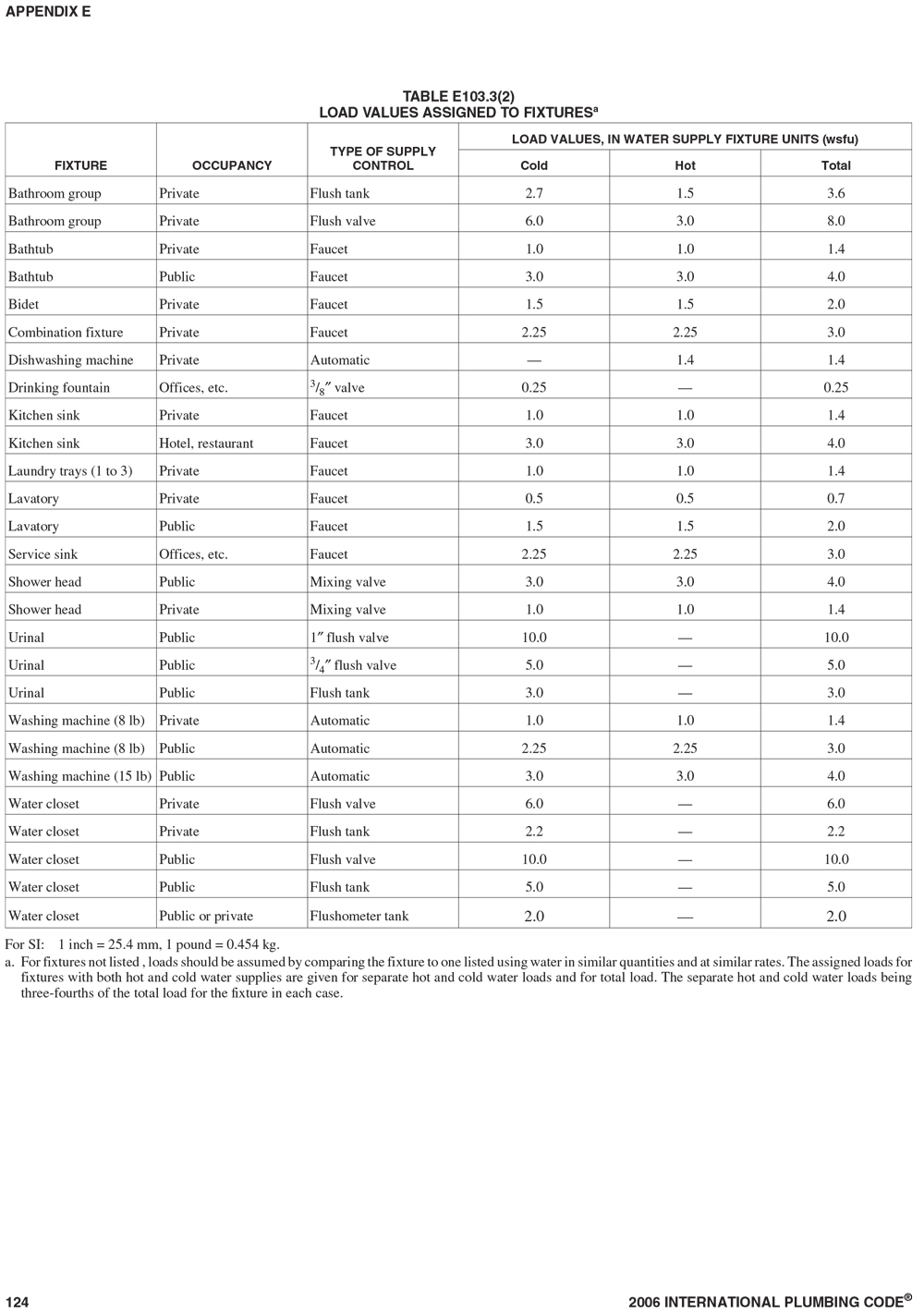

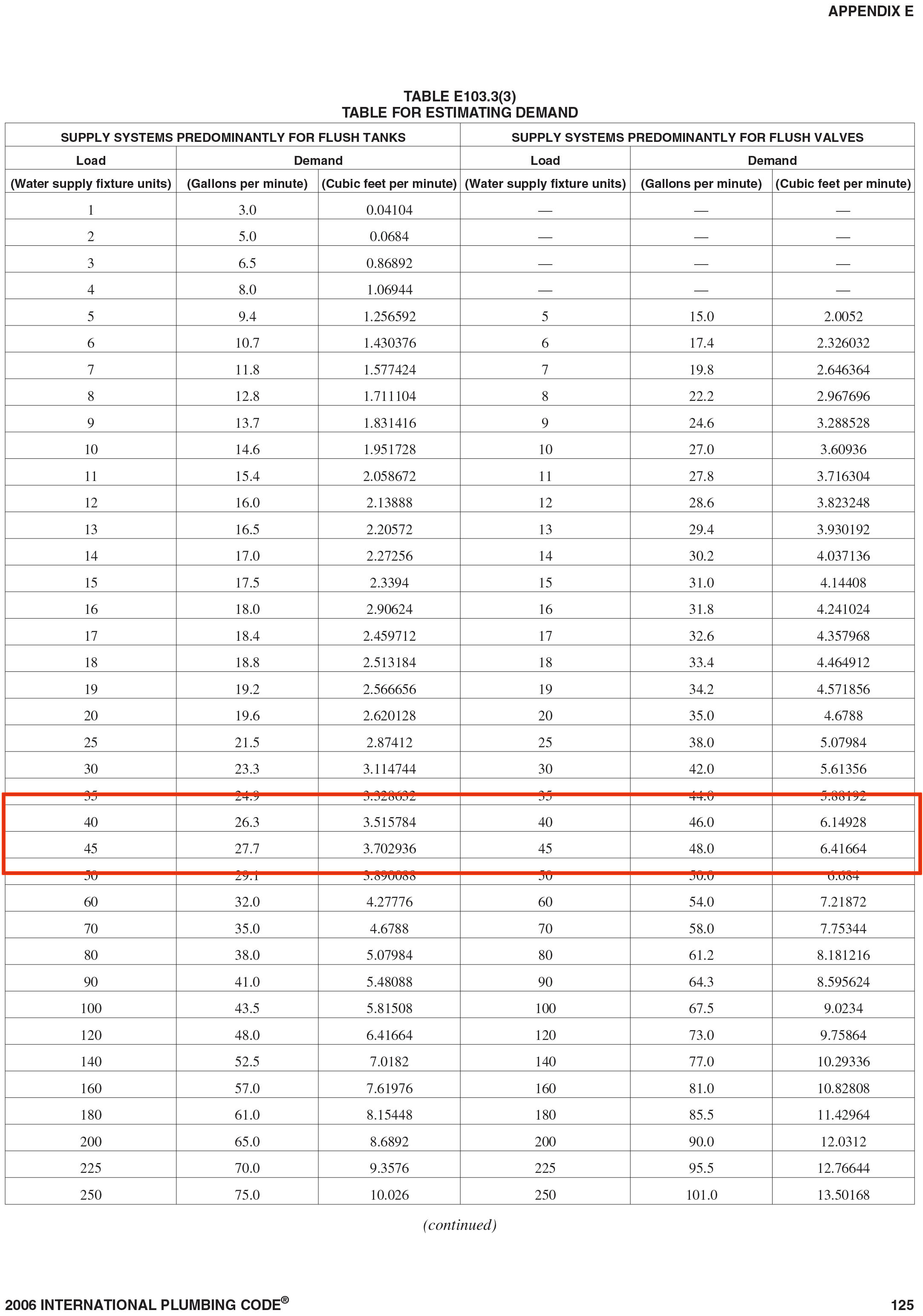

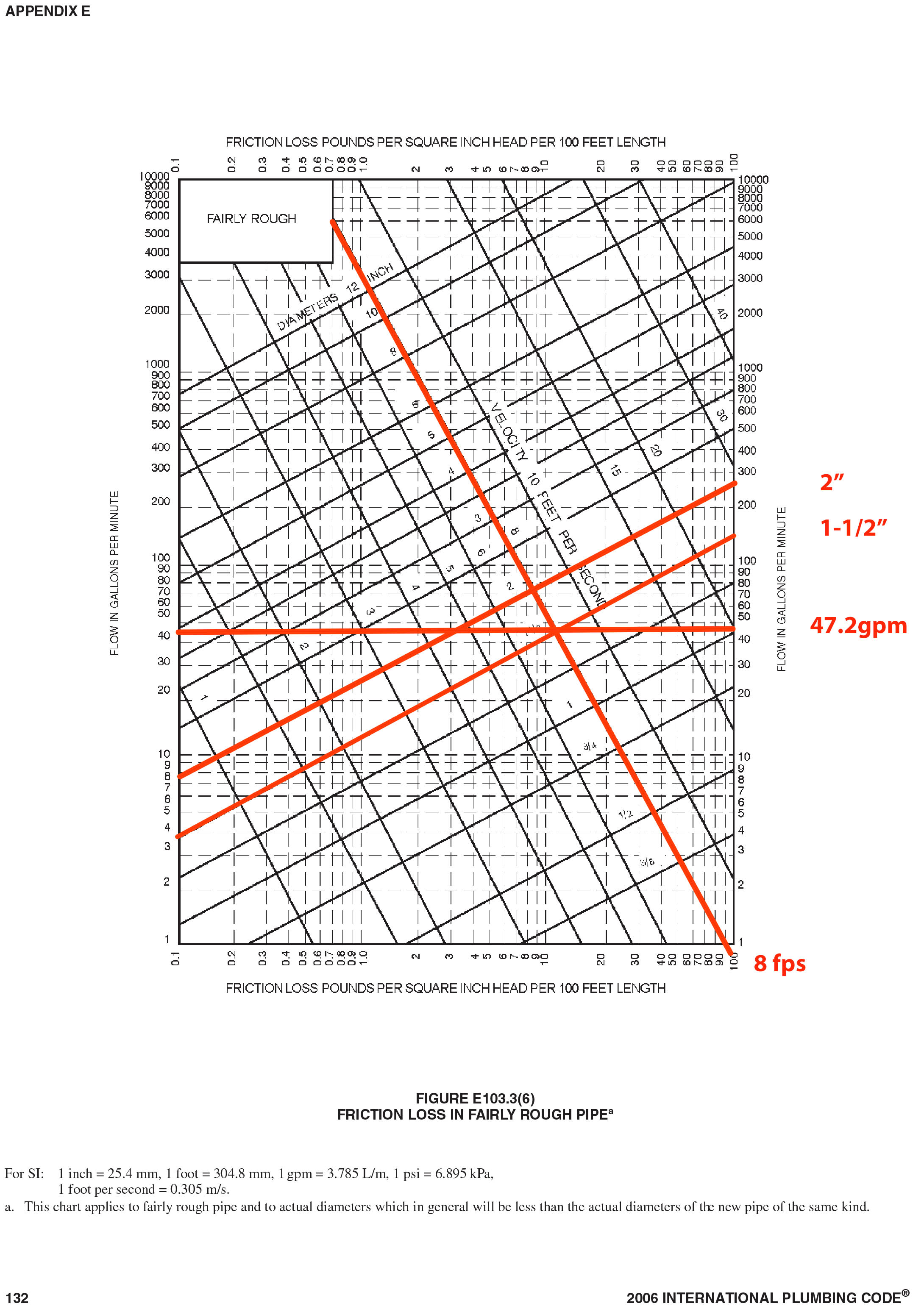

The wsfu values for typical plumbing fixtures are listed on IPC table E103.3(2) (Figure 1). Locate the type of fixtures to be used in the facility and then add up the total wsfu values for all plumbing fixtures being served. Find the number closest to the wsfu value on Table E103.3(3) (Figure 2) to estimate system demand in gallons per minute (gpm). Because the chart includes the supply required for both flush tanks and flush valves, you must determine if the system is predominantly one or the other, bearing in mind that most commercial jobs will be flush valve. Most likely, the number you calculated in step one is in between wsfu values found in the second chart. This means you will have to Interpolate to find demand, which will be illustrated in the upcoming example. Finally, IPC Chart E103.3(6) (figure 3) enables you to determine the pipe size using the appropriate demand vs. friction loss curves.

The following example illustrates how all of this works. Let’s assume you are assigned to determine the domestic cold water for a public bathroom with four flush valve water closets and two lavatories. You can tell by using the IPC chart (see figure 1) that the wsfu values are 10 for the water closets and 1.5 each for the lavatories. The total wsfu required is calculated like this:

WCs: 4 X 10 wsfu = 40 wsfu

2 Lavs: 2 X 1.5 wsfu = 3 wsfu

Total wsfu: 40 + 3 = 43

When you look for this number on the Table for Estimating Demand, (Figure 2), you see that the total wsfu of 43 falls in between to listed loads: 40 and 45. This is where it is necessary to interpolate the actual demand. To accomplish this, use a formula that determines the difference between the two load amounts and the related gpm’s. In our example, it would look like this:

𝐷𝑒𝑚𝑎𝑛𝑑=48−(48−46)∗(45−43)(45−40) 𝐷𝑒𝑚𝑎𝑛𝑑=47.2 gpm

Finally, you turn to “Friction Loss in Fairly Rough Pipe” table (figure 3) to determine the proper size pipe for the application in our example. Assuming a maximum velocity of eight feet per second (fps), we will plot on the graph where our demand (47.2) meets this velocity. From that point, you select the nearest pipe size to the left of the 8 fps velocity curve. In this example, you will select a two inch pipe. If you want to know the pressure drop, calculate it by reading the friction loss from the bottom of the chart.

Now that you have seen how to use the IPC charts and tables, you are ready to quickly and accurately size plumbing piping systems.

Get the scoop on shut down coordination in manufacturing plants.